Smarter Solutions Beyond OEM Limitations

Taka Turbo provides reverse engineering and part manufacturing services to ensure the availability and reliability of critical turbomachinery components. Covering both rotary and stationary parts, all engineering and manufacturing activities are performed in accordance with international standards such as API, ISO, and ASME, ensuring mechanical integrity, dimensional accuracy, and consistent quality.

Advanced digital engineering tools, including FEA and CFD, are applied to validate structural strength, dynamic behavior, and operational performance against defined acceptance criteria.

Beyond component replication, Taka Turbo emphasizes continuous improvement and innovation by optimizing designs, materials, and manufacturing processes in line with the latest technological developments.

This approach helps customers reduce dependency on OEM lead times, extend equipment lifecycle, and maintain operational continuity with high-quality, fit-for-purpose components that deliver long-term performance assurance.

Key Services

Rotary Parts

Stationary Parts

Key Facilities

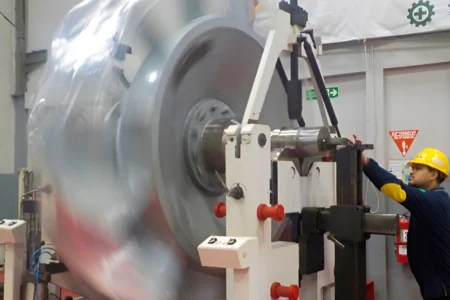

Our engineering division is equipped with advanced design, measurement, and machining technologies to support re-engineering and quality assurance with high precision.

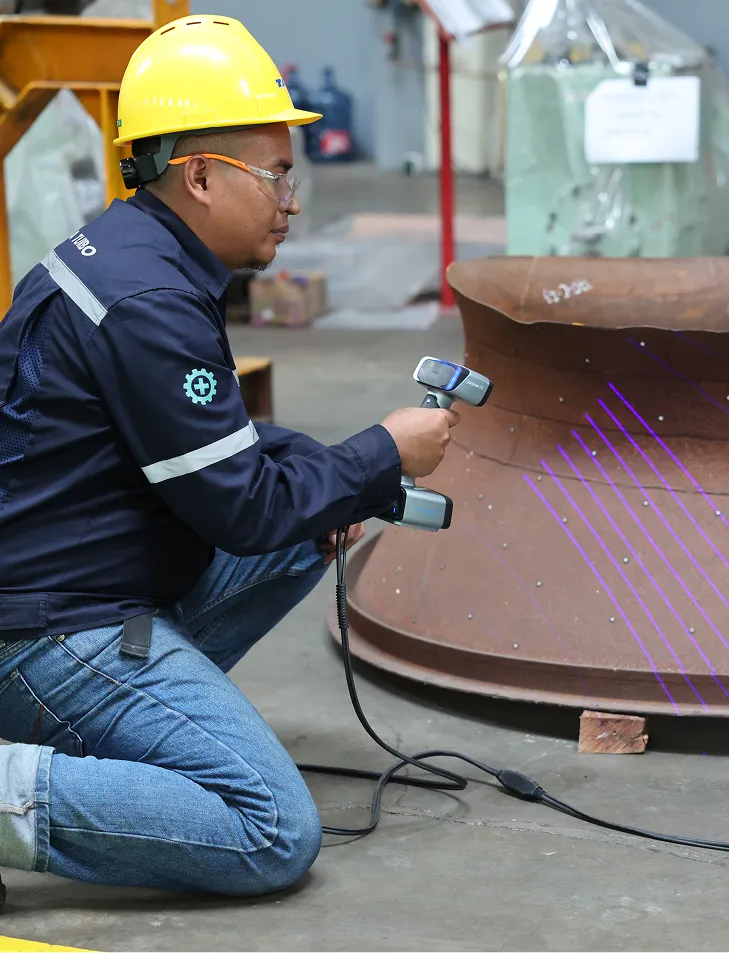

Advanced measurement and modeling systems for component analysis and reproduction.

- 3D Scan Machine

- Portable CMM Hexagon™

- CAD/CAM Integrated CNC Milling Machines (Hurco VMX 42, VM 24)

High-performance welding and coating systems for refurbishment and protection.

- TIG Welding (Miller Syncrowave 250–350 LX)

- Laser Welding (Robotic)

- Submerged Arc Welding (SAW)

- Thermal Spray / HVOF (Sulzer Metco DJ 2700)

Precision finishing and surface treatment tools for restoration and performance enhancement.

- Surface Grinding Machine (HMTW M7130)

- Burnishing Tool (Elliot Tool Tech S2300-001)

- Surface Roughness Comparator (Starret Microfinish)

Material and quality verification systems ensuring engineering precision and reliability.

- Positive Material Identification (Thermo Scientific)

- Hardness Tester (GE 35158 LPU 8R1)

- Coating Thickness Gauge (Time Group Unc TT2202)

- Rotor Weight Measurement (Nagata / Dillon up to 50 Ton)

Up-to-date licensed software that supports engineering services to be more precise and deliver optimal results.

- Solidworks Premium

- Solidworks Flow Simulation

- Autodesk Inventor Professional