Sector:

Related Services:

Year:

2021As one of the largest power plants in North Sumatra, PT Indonesia Power Pangkalan Susu OMU required a reliable Induced Draft (ID) Fan system to support boiler combustion and ensure high efficiency for its 135 MW power generation unit.

To meet this demand, Taka Turbo was entrusted to perform the complete manufacturing of the ID Fan Rotor and Stator set, covering all production stages from forging to final balancing.

Project Focus

Taka Turbo handled the entire manufacturing process under strict engineering standards to ensure durability, precision, and long-term operational reliability. The scope of work included:

- Forging Shaft – producing the shaft through hot forging for maximum mechanical strength.

- Casting Hub – precision casting of the hub using high-grade materials for balanced rotation.

- Static Casing Manufacture – welding and fabrication of the fan casing for high-pressure endurance.

- Machining Shaft – precision machining to achieve tight geometric tolerances.

- Impeller Fabrication & Welding – manufacturing and joining of impeller blades using industrial-grade welding techniques.

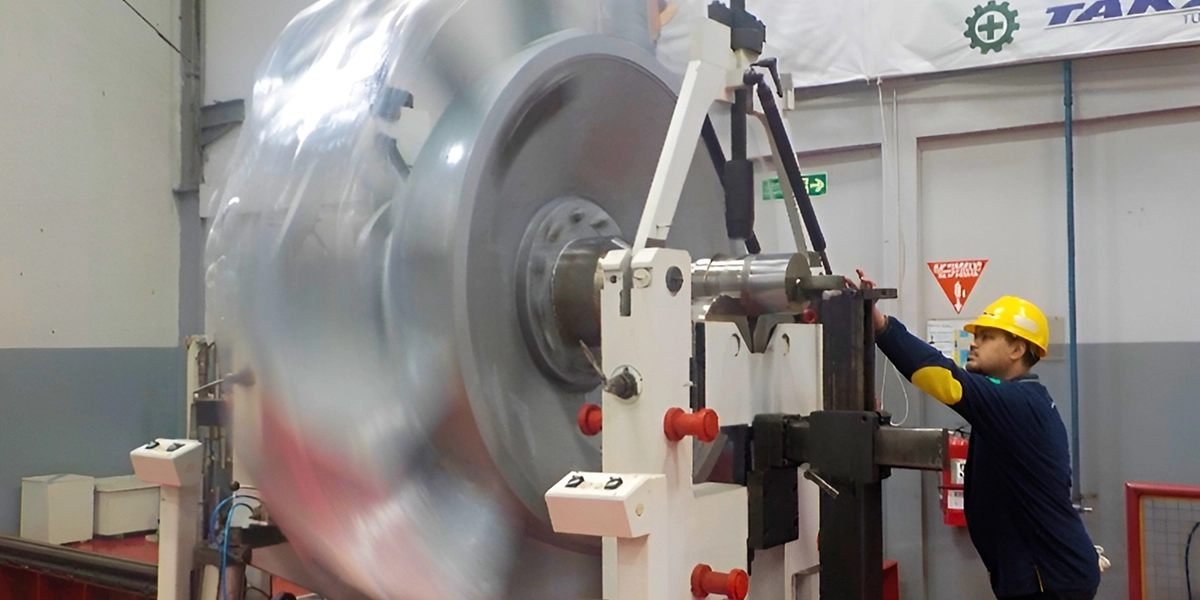

- Dynamic Balancing – performing high-precision balancing to ensure smooth, vibration-free operation.

Results

- A complete ID Fan Rotor and Stator assembly was successfully manufactured with exceptional precision.

- Mechanical and aerodynamic performance met all operational standards of Indonesia Power.

- Balancing test achieved minimal vibration and maximum efficiency.

- Project completed on schedule and fully compliant with client specifications.

Impact

This project reinforces Taka Turbo’s expertise in industrial manufacturing, delivering end-to-end engineering and production capabilities that support the reliability and performance of Indonesia’s power generation infrastructure.

Transform Your Operational Challenges Into the Next Success Story

Get in touch with our experts for fast, reliable service on all your rotating equipment and turbomachinery needs.