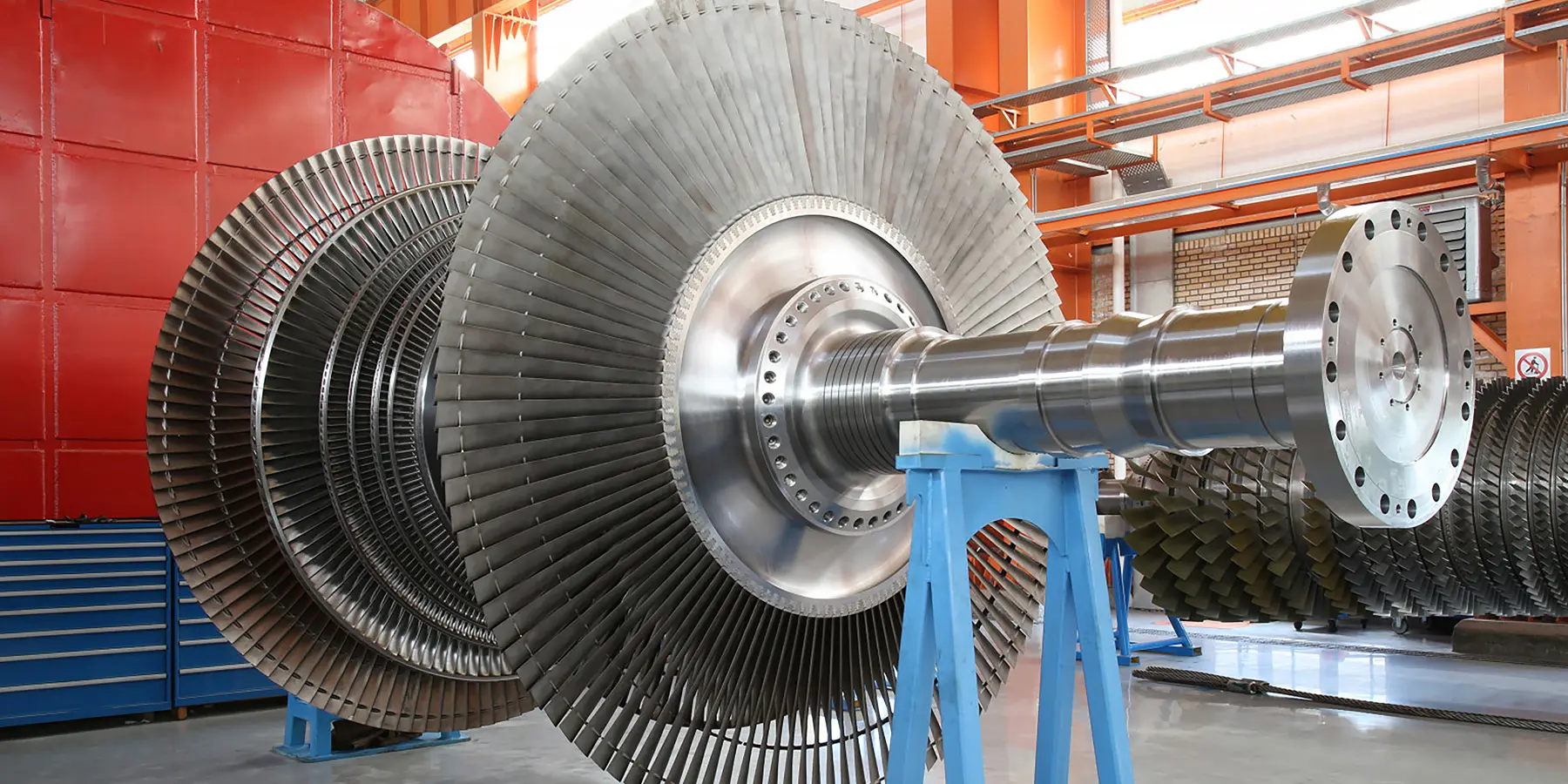

Turbomachinery is at the heart of modern industry, powering energy plants, refineries, petrochemical facilities, and other critical sectors. Gas turbines, steam turbines, compressors, pumps, and gearboxes work continuously under extreme conditions. Without proper maintenance, these machines can suffer from reduced efficiency, unexpected breakdowns, and costly downtime.

Understanding what turbomachinery is, how it works, and why regular maintenance is crucial can help industries extend equipment lifespan, reduce operational risks, and improve overall performance.

What is Turbomachinery?

Turbomachinery refers to machines that transfer energy between a rotor and a fluid, including turbines, compressors, pumps, and fans. They are widely used in:

- Power Generation – steam turbines and gas turbines generate electricity.

- Oil & Gas – compressors and pumps drive critical processes.

- Petrochemical & Fertilizer – rotating equipment maintains chemical production flows.

- Mining & Heavy Industries – equipment supports material processing and resource extraction.

- In short, turbomachinery is the backbone of industrial operations. If it stops, entire production lines can halt.

Why Regular Maintenance is Essential

Like any high-performance machine, turbomachinery requires preventive and corrective maintenance to function optimally. Regular maintenance brings multiple benefits:

Improved Reliability

Routine inspections and servicing reduce the risk of sudden breakdowns, ensuring equipment runs smoothly when needed most.

Extended Equipment Lifespan

Overhauls, refurbishments, and part replacements help extend the operational life of turbines, compressors, and pumps.

Optimized Efficiency

Proper calibration, balancing, and cleaning minimize energy loss, reducing fuel consumption and operating costs.

Safety Compliance

Maintenance ensures that equipment meets international HSE (Health, Safety, and Environment) standards, reducing risks to workers and communities.

Cost Savings

Planned maintenance is always cheaper than emergency repairs or replacing an entire machine after catastrophic failure.

Common Maintenance Practices in Turbomachinery

Industries typically rely on several key practices to keep turbomachinery in peak condition:

- Inspection Services – early detection of wear, cracks, or imbalance.

- Workshop Repair – refurbishment, welding, machining, and re-engineering.

- Onsite Repair – re-blading, build-up, and balancing without equipment relocation.

- Field Services – major and minor overhauls, plant turnaround, and unit relocation.

- Reverse Engineering – producing rotary and stationary parts when OEM supply is limited.

The Role of a Trusted Partner

Maintaining turbomachinery requires not just tools, but expertise, facilities, and proven experience. A trusted service provider like Taka Turbo brings together:

- Advanced workshop facilities (8,500+ sqm, 125-ton balancing machine, CNC machining, HVOF coating).

- Over 100 certified Indonesian engineers and technicians.

- Full compliance with ISO 9001, ISO 14001, and OHSAS 45001 safety standards.

- 24/7 readiness for emergency call-outs.

With this combination, industries can minimize downtime, optimize performance, and ensure operational continuity.

Conclusion

Turbomachinery is too critical to leave to chance. Regular maintenance is not just an option, but a necessity for industries that depend on reliable power and production. By investing in inspections, repairs, and sustainable solutions, companies can secure long-term operational success.

For businesses in Indonesia and beyond, Taka Turbo provides the expertise, facilities, and commitment needed to keep turbomachinery running at peak performance—today and in the future.

Transform Your Operational Challenges Into the Next Success Story

Get in touch with our experts for fast, reliable service on all your rotating equipment and turbomachinery needs.